In the world of motor production, innovation is key to efficiency and sustainability. One significant advancement lies in the elimination of water cooling systems in patented motors. This shift brings a range of advantages, revolutionizing the way motors function while addressing several key drawbacks associated with traditional water-cooled systems. Water cooling, while effective in some regards, presents various challenges and limitations. Firstly, it requires substantial initial investment, involving the setup of complex systems including piping, flow monitoring, temperature controllers, and cabling. This not only adds to the overall cost but also demands continuous maintenance, leading to increased operational expenses. Moreover, the dependence on water quality is a significant concern. Water-cooled systems mandate chemically and physically clean water, posing challenges in various environmental conditions. Factors like temperature and climate directly impact the motor's performance, making it susceptible to external influences beyond its control. One critical drawback is the power consumption of the pump used in water cooling, which significantly affects the motor's overall power output. This power drain not only impacts efficiency but also translates into higher operational costs. Furthermore, the risk of system failure in water cooling can lead to severe damage to the motor. A malfunction in the cooling system poses a threat to the entire operational integrity, potentially causing irreparable harm and costly repairs. However, by eliminating water cooling, these challenges are effectively mitigated. The patented motors operate efficiently without the need for water-based cooling systems. This not only reduces initial investment costs but also slashes maintenance requirements, thereby enhancing cost-effectiveness and reliability. The elimination of water cooling systems also ensures consistent motor performance regardless of external climate conditions. This independence from environmental factors results in a more robust and reliable motor, delivering steady performance over time. Moreover, without the energy-consuming pumps and complex cooling infrastructure, these motors offer increased energy efficiency and higher power output. This translates to reduced operational costs and a smaller environmental footprint, aligning with the global push for sustainability. In conclusion, the move towards patented motors that eliminate water cooling systems marks a significant leap in motor technology. By addressing the drawbacks associated with traditional water-cooled systems, these motors offer enhanced efficiency, reliability, and sustainability, revolutionizing the landscape of motor production and operation.

1 Comment

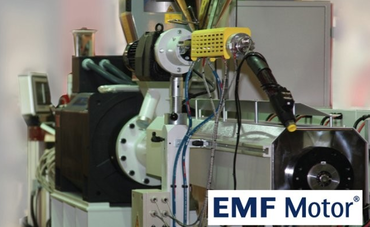

Revolutionary Direct Drive Motor for ExtruderThe EMF Motor Company aims to redefine the extrusion process with its Direct Drive motor unveiled at Fakuma 2023.

Share Email Just before the start of Fakuma, the EMF Motor Company announced that visitors to the exhibition can witness a groundbreaking change in the world of plastic manufacturing. The EMF Motor Company will unveil its patented Direct Drive motor principle in Friedrichshafen, aiming to redefine extrusion processes with a strong focus on sustainability. Direct Drive Motor Improves Extrusion Quality The EMF Motor Company highlights high extrusion quality as the primary benefit of its new Direct Drive motor: "Say goodbye to conventional gears, as our Direct Drive system guarantees extrusion quality at the highest level," says the company. Very High Torque Density and Energy Efficiency Additionally, the new drive is characterized by stable torque and minimal torque fluctuations, even at low speeds of only 0.1 rpm. According to EMF, the patented principle also offers unmatched torque density and reduces resource consumption. The high efficiency at low speeds and precise speed control contribute to minimizing material waste. No Water Cooling Needed Despite High Performance Despite its high performance, the Direct Drive motor, thanks to innovative EMF technology, does not require water cooling. EMF emphasizes that the maintenance-free Direct Drive motor principle eliminates the need for maintenance, reducing environmental impact. Moreover, EMF motors are designed to minimize copper losses, increase efficiency, lower operating costs, and promote environmentally friendly production. EMF even refers to the motor as the "Master of Green Energy" because of its outstanding energy efficiency, which can reduce the energy consumption and, consequently, the CO2 footprint of the plastic industry. To further enhance efficiency, the Direct Drive motor can be tailored to specific application needs by choosing the appropriate pole numbers. At Fakuma, the EMF Motor Company will showcase its Direct Drive motor principle in action, demonstrating to visitors how the new solution can transform the plastic industry, improve production quality, and lead the sector into a greener, more efficient future.

The classical extruder machine comprises an AC-Motor, a gearbox and/or belt and/or a cooling system.. Each used additional component reduces the efficiency of the machine. Initial investment costs, maintenance costs, component lifetimes are one of the major problems. You can eliminate all these problems and have more efficient, more quality extrusions by using SQME Extruder Torque Motor.

"EMF Motor, the innovative solution for excellent extrusion" The advantages of SQME Extruder Motor

The high pole number allows great speed stability for precise extrusion which is very important for medical hose, film, cable industries and laboratory. Who is EMF Motor? EMF Motor manufactures precision motors for decreasing the energy costs and reducing the manufacturing losses of its customers, as well as for increasing manufacturing speeds and providing high quality products. (*) Extrusion description on wikipedia Published on Linkedin : SQME Extruder Motor, for a better extrusion quality | LinkedIn |

Archives

December 2023

|

HoursM-F: 7:30am - 5:15pm

|

TelephonePbx +90 216 595 19 00

Fax +90 216 595 19 01 |

|

RSS Feed

RSS Feed