|

EMF Motor presents the world's most efficient motor with patented PM technology which offers perfect solutions for cooling tower application.

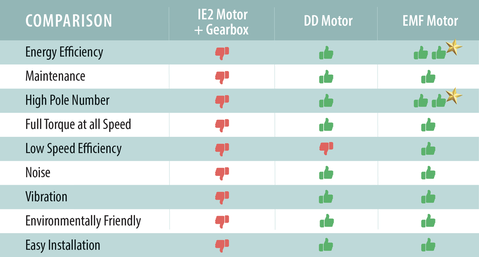

Our patented motor technology enables us to produce gearless, high pole number (66-88-110) and very efficienct motors. It offers reliable speed control, reduced maintenance, quieter operation and unbeatable high energy saving. The fan couples directly to the motor and can be controlled by sensorless flux vector drivers. Due to the high number of magnetic poles, high torque is achieved with reduced rotational speed. The motor winding losses are much less than conventional high pole motors. The motor enables a high efficiency even at very low speeds. |

Direct Drive Technology

|

Case Study: Cooling Tower Motor Upgrade

|

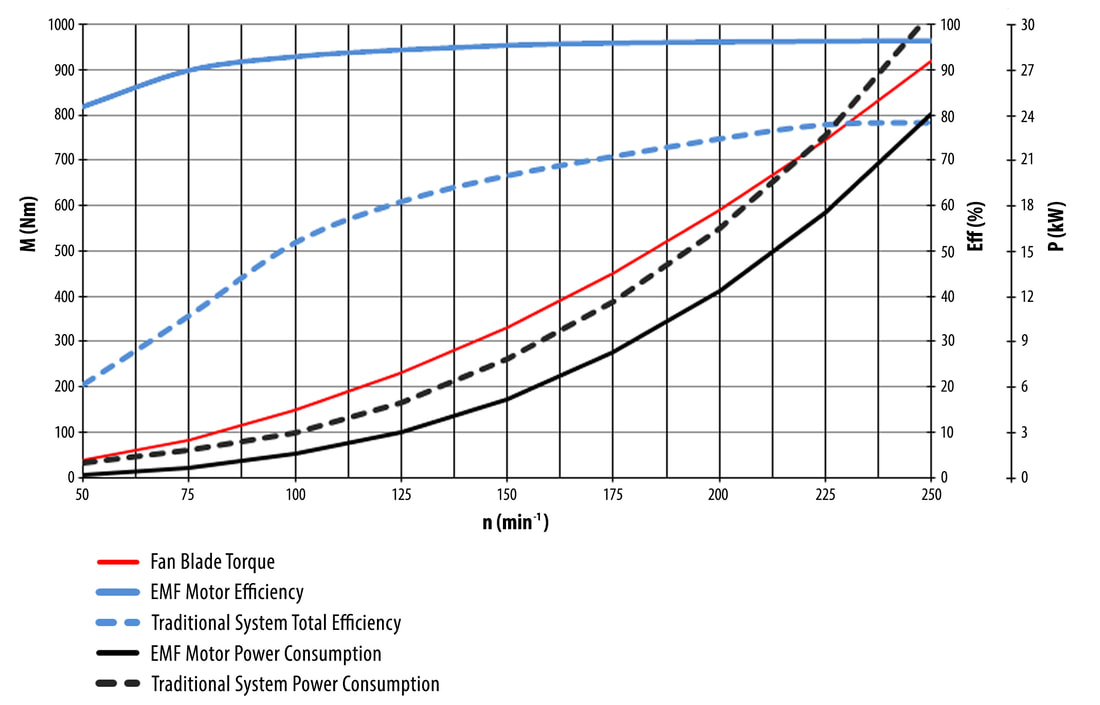

Old Conventional System

• 37 kW, 1,470 rpm, IE2 AC motor • Connected to gearbox (i = 6.1) • 3-meter shaft with couplings • Propeller at 4 degrees • Consumed 33.5 kW • No mention of efficiency or voltage Replacement • Old system replaced with existing fan • Propeller angle set to 8 degrees • Both systems have airspeed of 10.2 m/sec and airflow of 193 m³/sec Benefits • Reduced maintenance and costs • Improved reliability • Quieter operation (6 dB less) • Easy installation ( Compact Design ) |

Replaced with SQMC200-400 Motor

• 25 kW, 208 rpm, 1150 Nm • Efficiency: 93% • Nominal voltage: 354 V, 62 A • Driven by inverter Energy Effciency • Conventional system consumes 27,6% more Energy • Estimated electrical Cost Savings of 4.500 €/year • Payback period is short due to Cost Savings |

|

Advantages of SQMC Motor

|

|

|