|

SQME Extruder Motor is the permanent magnet synchronous motor which has the patented motor principle. It is the perfect solution for low speed and high torque extrusion applications.

CHARACTERISTICS OF SQME MOTOR FOR EXTRUDERS

Other Advantages of Patented Motor Principle

EXAMPLE OF ENERGY SAVING

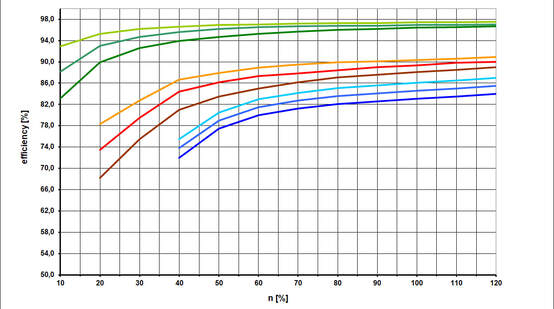

The above comparison chart is shown the advantage of EMF Motor’s synchronous torque motors with german patented motor technology. As EMF Motor family, we value sustainability.

|

Plastic Film Extruder Machine with Direct Drive Motor

Medical Extruder Machine

with Direct Drive Motor Extruder for Disposable Plastic Table Cloth by EMF Motor

Twin Screw Extruder for Profile with Direct Drive Motor

Success Story by Extruder Machine with Direct Drive Motor

Extrusion Applications by EMF Motor

|

EMF Motor customers produce and save..