Direct Drive

Technology

Pure Torque. Zero Loss. Gearless. Silent.

Products

Engineered for excellence. Every solution is designed with precision and built to last.

Torque Motor

SQM Synchronous Torque Motor with patented EMF Motor principle - the highest efficiency motor technology

Cooling Tower

High efficiency direct drive motor for cooling tower applications with corrosion protection

Extruder Motor

Direct Drive solution for all extrusion applications - gearless, maintenance-free, and highly efficient

HVLS Fan

Patented NEW technology for cooling and ventilation with HVLS industrial ceiling fans

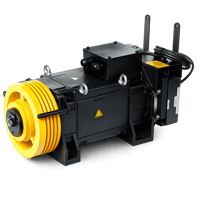

Lift Motor

Gearless lift motors with high efficiency, silent operation and maintenance-free design

Mill Motor

Direct Drive solution for grinding applications

Applications

Specialized motor solutions for diverse industrial applications

Extruder Motor

Plastic and rubber industry solutions

ApplicationCooling Tower

HVAC and cooling tower systems

ApplicationHVLS Fan

Large space ventilation and air circulation

ApplicationMill Motor

Feed roll and milling applications

ApplicationLift Motor

Elevator and lifting systems

Applicationproduct_winder

Winder and unwinder solutions

Industries We Serve

From plastics to elevators, our motors power the worlds most demanding applications.

Plastics & Extrusion

Food & Beverage

Glass & Ceramic

Metal Processing

Elevators & Lifts

HVAC & Cooling

Textile & Fiber

Renewable Energy

Cement

Data Centers

HVLS Fans

Marina

Mining

Paper

Upcoming Events

Visit us at these upcoming trade shows and exhibitions.

AHR EXPO 2026

The world's largest HVACR event. Visit us at Stand SU856.

Fakuma 2026

International trade fair for plastics processing.

Chillventa 2026

World's leading trade fair for refrigeration technology.

Engineering Excellence

Numbers that define our commitment to quality and innovation

Get in Touch

Ready to transform your operations? Lets discuss how EMF Motor can power your success.

or email us at info@emfmotor.com